Study on the relationship between industrial depth, connector durability and microstructure of copper and copper alloy strips

Release time:2022-02-25Click:979

ABSRTACT: Based on the microstructure and properties of copper and copper alloy strips, which are one of the important basic materials of connectors, the relationship between the properties and the durability of connectors is analyzed. The texture and grain size of copper and copper alloy tapes are directly related to the durability of connectors.

Durability is an important parameter of connector reliability. As to how to test the durability of connectors, some standards have been established at home and abroad, such as EIA-364-09C and GB/t5095 -- 1997(equivalent to IEC512 -- 1993) . Due to the destructive nature of durability testing, which requires more time and cost, the electronic component plant or finished product plant uses this method during the type testing and validation phase of the product. In order to ensure the durability of connectors, connector industry designers often use maximum stress method or nominal stress method to design the structure of connectors. The maximum stress or nominal stress is less than the yield strength of the material, and the durability of the connector is calculated according to the stress-life curve (S-N curve) . Although the maximum stress method or the nominal stress method solves the problem of calculating the durability of connectors in theory, the durability of connectors is often inconsistent with the theoretical data in the application of connectors, it brings unnecessary losses to the users. How to solve this problem is a common problem for connector manufacturers and users.

A great deal of research has been done to improve the durability of connectors from the aspects of material selection parameters, positive force or plug force, plating material, Surface roughness and lubrication conditions. Copper and copper alloy tape is one of the most important basic materials for connectors. However, little research has been done on the relationship between the properties of copper and copper alloy tape and the durability of connectors.

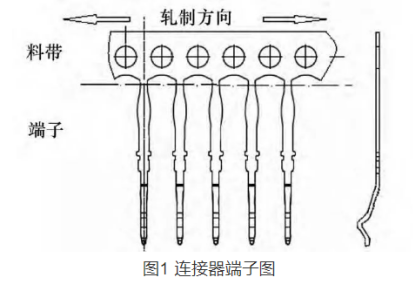

1 Connector terminal structure the terminals of the connectors are usually made of continuous die tape in the form of high-speed precision punch press, which have the characteristics of large demand, ultra-thin, complex shape and high precision. The terminal is generally composed of a curved head structure and a slender cantilever structure, as shown in figure 1.

In order to improve production efficiency and save costs, after high-speed stamping and electroplating, the connector assembly process, the manufacturer will be cut off from the material belt for assembly.

(2) The microstructure and properties of copper and copper alloy tapes have been developed through years of manufacture of copper alloy tapes, the main manufacturing methods of copper and copper alloy strip for connector can be summarized as: semi-continuous casting or continuous casting, milling blank surface, multi-rolling (including multi-heat treatment) , finishing, surface treatment and so on. As the rolling process of copper and Copper Alloy Strip is one-way rolling along the rolling direction, the crystal of copper and copper alloy strip gradually forms rolling texture with the increase of rolling deformation degree. In addition, the different heat treatment after rolling and the different deformation degree before heat treatment, the crystal of copper and copper alloy strip will have different recrystallization texture.

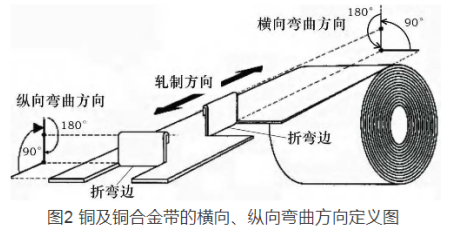

Texture will bring the discordance phenomenon, I. E. Anisotropy, to the physical and mechanical properties of copper and copper alloys in different directions. For example, it has been proved by research and practice at home and abroad that the bending properties of copper and copper alloy strip in Good Way and Bad Way are quite different, the Longitudinal Properties of copper and copper alloy strip are better than the transverse properties. The Bad Way and the Good Way of the copper and copper alloy tape are defined in figure 2.

In the national standards YS/t 1041(2015) and GB/t 26007(2010) for copper and copper alloy strips for Automotive Terminal Connectors, and ASTM B888/888M-13“Standard specification for copper alloy strip for electrical connector or spring contact production”clearly define the different longitudinal and transverse bending parameters of copper and copper alloy strip. When copper and Copper Alloy Strips are bent, the outer surface is deformed in a manner similar to that of tensile test. During the bending process, the tensile strength of the outer surface layer increases, and elastic deformation, plastic deformation and cracking occur gradually. The Longitudinal Bending property of copper and copper alloy strip is better than that of transverse bending, which shows that the Longitudinal tensile strength or yield strength of copper and copper alloy strip is better than that of transverse bending.

3 Correlation Study 3.1 transverse yield strength

As the National Standard Gb/t 26007(2010) and YS/t 1041(2015) , the tensile strength and yield strength of copper and copper alloy strips are longitudinal parameters. When the connector designer designs the connector life, all take the longitudinal direction parameter as the basis. Due to the constant pressure of cost, the terminals of connectors are generally plated with precious metals such as gold, most of which are distributed in the transverse direction (Fig. 1) . That is, the design parameters of in-connector durability are inconsistent with the actual parameters. And stamping factory or connector factory received copper and copper alloy belt, has not easy to test the specific strength of the transverse direction. Most factories use vickers hardness to check the strength performance of incoming materials. This method has big error and can not distinguish the difference of Longitudinal and transverse parameters. This is one of the reasons why the actual mechanical life of some connectors is shorter than the design life. The tensile strength, yield strength and elongation in the transverse direction of copper and copper alloy strip can be measured conveniently by copper strip mill before strip separation. In order to ensure the durability of the connector, the connector factory needs the copper strip factory to provide the Longitudinal and transverse mechanical strength parameters of the copper and copper alloy strip. 3.2 Bending Property r/t value of copper and copper alloy tape directly affects the forming ability of connector terminals. Both ASTM B820“Test methods for determining the formability of copper and copper alloy strips”and YS/t 1041 -- 2015“Copper and copper alloy strips for automotive terminal connectors”require longitudinal and transverse bend direction sampling testing.

Only the American standard requires the method of judging no visible crack on the bending surface of the specimen after the bending test is observed with 30X magnification instrument. The domestic standard requires the naked eye to observe the specimen bending surface without visible cracks. Theoretically, the bending properties of copper and copper alloy strips tested according to domestic standards are worse than those of copper and copper alloy strips tested according to American standards. Connectors made of this material are also less durable than connectors made of copper and copper alloy substrates tested according to American standards. To improve the durability of connectors, connector factories and copper strip manufacturers should use more stringent standards to check the r/t values of copper and copper alloys for bending properties. 3.3 grain size and uniformity at present, grain refinement (including grain uniformity) is a commonly used method to improve the mechanical properties of copper and copper alloy ribbons. With the research and experiment of ultra-fine grain and nano-grain, the grain size can act as a dominant factor on the mechanical properties of copper and copper alloy bands in a certain range, the dominant factors affecting the mechanical properties of copper and copper alloy strips will be changed, and the Houle-Petch formula will no longer be valid, that is, the anti-Houle-Petch phenomenon will appear.

In the study of Nanocrystals, the distribution of grain size also affects the mechanical properties of copper and copper alloy ribbons to a great extent, at the same time, it also keeps the original strength higher than other fine grain materials. In the mass industrial production of copper and copper alloy strips, the application of Houle-Petch formula is still dominant. The fine grain size of industrial copper and copper alloy belts in China can be controlled at about 10 Μm, and the fine grain size of some copper belts can be controlled at about 5 μm. The industrial production of ultra-fine Grain Copper Strip has been realized in Germany, Japan and other countries by using accumulative roll-up (synchronous roll-up) technology. In the actual use of connectors, copper and copper alloy strips with small grain size and good uniformity have better mechanical properties, and the connectors made by them have better durability.

4 Conclusion 1) because of the anisotropy of copper and Copper Alloy Strip, the yield strength in the Rolling Direction (Longitudinal Direction) is better than that in the vertical direction (transverse direction) . 2) according to the manufacture characteristic of connector terminal and the usage characteristic of connector, the Copper Strip factory should provide and guarantee the vertical rolling (transverse) yield strength on the basis of the mechanical property of the Rolling Direction (Longitudinal) . 3) ASTM B820-14A is higher than the current standard in our country on the rigour and applicability of copper and copper alloy strip bending test. The higher the durability and mechanical life of products with copper and copper alloy strips tested using more stringent standards. 4) within the scope of the Houle Petch equation, copper and copper alloy strips with smaller grain sizes can increase the durability of connectors.

Source: Automotive Electronics 2018 issue 2 by Zhang Xin

Disclaimer: Some pictures and texts on this site are collected from the Internet and are only for learning and communication. The copyright belongs to the original author and does not represent the views of our site. This site will not bear any legal responsibility. If your rights are violated, please contact us to delete it in time.