Copper bars play a role in conveying current and connecting electrical equipment in circuits

Release time:2024-03-05Click:401

Copper busbar, also known as copper busbar, copper busbar or copper busbar, grounding copper busbar, is a long conductor made of copper material with a rectangular or chamfered (rounded) cross-section. It plays a role in conveying current and connecting electrical equipment in circuits.

Copper bar is a high current conductive product with high mechanical properties, good conductivity, thermal conductivity, excellent corrosion resistance, electroplating, brazing, beautiful metal luster, and good forming and processing performance. It is suitable for high and low voltage electrical appliances, switch contacts, distribution equipment, bus ducts and other electrical engineering. It is also widely used in metal smelting, electrochemical electroplating, chemical caustic soda and other ultra high current electrolytic smelting projects.

Due to the superior conductivity of copper compared to aluminum, copper bars have been widely used in electrical equipment, especially in complete power distribution devices. Generally, copper bars are used for the U, V, W phase busbar and PE busbar in the distribution cabinet; Copper bars are generally marked with phase color letters or painted with phase color paint during use. U-phase copper bars are painted with "yellow" color, V-phase copper bars are painted with "green" color, W-phase copper bars are painted with "red" color, and PE busbar copper bars are painted with "yellow green alternating" dual colors.

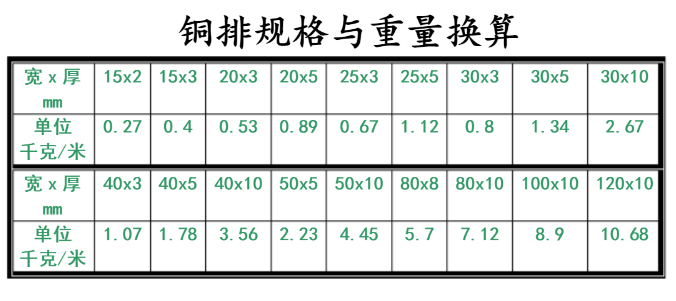

Common specifications and weight conversion table

Common specifications and weight conversion table of copper bars: The commonly used models of copper bars include: 15mm * 2mm, 15mm * 3mm, 20mm * 2mm, 20mm * 3mm, etc. Choose copper bar models according to different needs.

The characteristics of copper bars

1. Corrosion resistance: Copper has lower corrosion resistance than gold, platinum, silver, and titanium; Compared to metals such as iron, zinc, and magnesium, copper has stronger corrosion resistance. Compared to aluminum, copper is more resistant to corrosion from non oxidizing acids, alkalis, and seawater. However, aluminum has stronger corrosion resistance in atmospheric, weakly acidic, and other media than copper.

2. Easy to process and form: The strength of copper bars is moderate, about 200-360MPa, and the deformation resistance is greater than that of aluminum but much smaller than that of steel and titanium. Moreover, it has good plasticity and can withstand cold and hot pressure processing such as rolling, extrusion, forging, stretching, stamping, bending, etc. The deformation degree of rolling and stretching can reach over 95% without the need for intermediate annealing and other heat treatments.

3. Strong antibacterial properties: Copper bars can inhibit the growth of bacteria and other microorganisms, and 99% of bacteria in water will be completely killed within 5 hours in a copper environment. This is very important for drinking water transportation, food containers, marine engineering, etc.

4. Solderability: Copper bars are easy to weld using methods such as soft brazing, hard brazing, and gas shielded arc welding. Phosphorus containing a small amount of phosphorus is deoxidized, resulting in better copper welding performance. Due to the good thermal conductivity of copper bars, high-power welding facilities are required for copper bar welding, which requires gas protection and generally does not require spot welding.

5. Platability non-magnetic: Copper bars have platability and can be electroplated with high melting point metals such as nickel and chromium, as well as hot-dip plated with low melting point metals such as tin and zinc. At the same time, copper bars are non-magnetic metals, which play an important role in protecting the circuit.

Acceptance criteria for copper bars

Acceptance criteria for copper bars: For processed copper bars, acceptance should be carried out according to the following standards:

Material: National standard T2 copper

Copper content: Approximately 99.95%.

The surface of the copper bar is smooth and flat, without cracks, peeling, slag inclusion, pores, and other phenomena.

Surface smoothness 3.2

Dimensional deviation ± 0.5mm

Straightness ≤ 2mm/m

Curved 90 degrees with no cracks on the surface

Hardness: HB ≥ 65

Tensile strength: ≥ 300N/mm2

Density: 20 ℃ Copper bar density 8.95g/cm3

Electrical resistivity: ≤ 0.017772 Ω mm2/m