Application Research of Deep Metal Haowen, high strength copper-titanium Alloy

Release time:2022-02-17Click:953

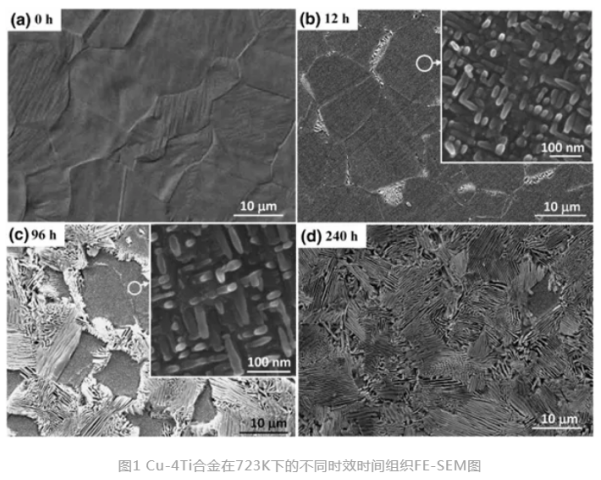

01 Alloy. According to the phase diagram of cu-ti alloy, the solubility of TI in 1% ~ 6% CU-TI alloy is very sensitive to temperature. The microstructure evolution of cu-ti alloy during aging process is shown in Fig. 1. With the increase of aging time, a large number of fine precipitates are precipitated in the grains first, and then a large number of cellular precipitates are precipitated in the grain boundaries. Therefore, the composition of Cu-ti alloy and aging time have an important effect on the microstructure of the alloy.

The cu-ti alloy has the behavior of amplitude modulation decomposition, which includes the segregation and ordering of Ti Atoms, which increases the hardness and strength of the alloy. The AM decomposition of the alloy starts with the quenching process, continues at the beginning of aging, and finally forms the am structure of Matrix + metastable phase. The temperature range of amplitude-modulated microstructure is narrow, the discontinuous cellular structure is easy to be precipitated during overaging, and the comprehensive properties of the alloy decrease. Therefore, to reduce the precipitation of cellular structure and improve the overall performance of the alloy, it is necessary to suppress the generation of am decomposition structure of cu-ti alloy. Some elements can restrain the am decomposition of Cu-ti alloy effectively, so new elements can be added to form multi-element Alloy to restrain the am decomposition of cu-ti alloy and improve the microstructure and properties of the alloy. In addition to the strengthening effect due to the contribution of am decomposition, the main reason for the strength increase of Cu-ti alloy after aging treatment is that the matrix precipitates continuously, the cell-like discontinuous precipitates are precipitated at the grain boundary by consumptive continuous precipitates, and the strength of the precipitates is greatly reduced. It can be seen that in order to reduce the cellular structure in the alloy, it is necessary to control not only the amplitude modulation decomposition but also the aging time to control the size and type of precipitates.

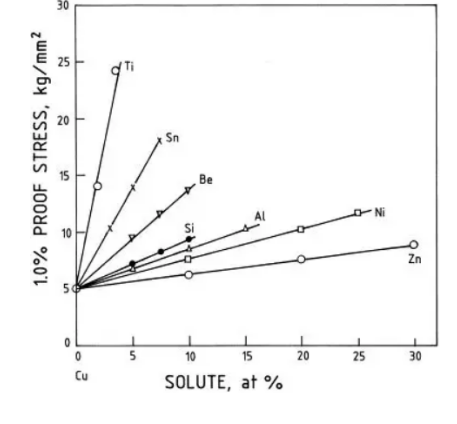

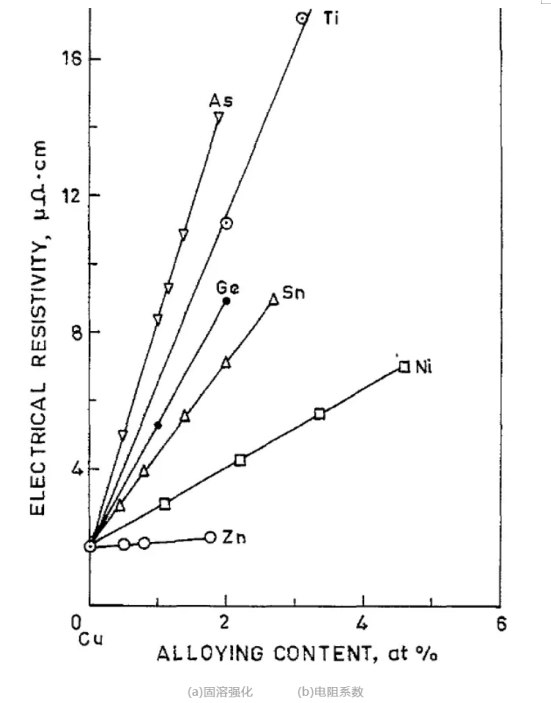

Fig. 2 solution strengthening effect and Resistance Coefficient of cu-ti alloy and other cu-based alloys. It can be seen that titanium atoms have very good solid solution effect on copper, so the cu-ti alloy has better mechanical properties after solid solution treatment. According to Mott-Nabarro’s theory, titanium atoms cause lattice distortion, and the resultant stress field interacts with the dislocation stress field, which impedes the dislocation motion and strengthens the alloy. However, the TI atoms in the matrix scatter more electrons, and the resistivity of cu-ti alloy is higher than that of other cu-based alloys. Therefore, the main problem of Cu-ti alloy is to solve the contradiction between properties and conductivity.

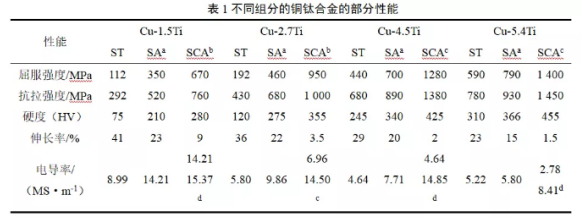

Some of the properties of low-concentration Cu-ti alloys are shown in Table 1, where St stands for solution treatment, SA stands for solution treatment + peak aging, SCA stands for solution treatment + 90% cold deformation + peak aging, a stands for 450 °C aging for 16 H, and B stands for 400 °C aging for 6 H C means aging at 400 °C for 1 H and d means aging at 450 °C for 24 H. It can be seen that the solution effect of CU-TI alloy increases with the increase of Ti content, the tensile strength, hardness and fatigue strength increase, but the electrical conductivity and elongation decrease. At the beginning of aging, fine-Cu4Ti precipitates are precipitated to form precipitation strengthening, which increases tensile strength, hardness and electrical conductivity, the growth of-Cu4Ti precipitates and the precipitation of Cellular Cu3ti precipitates at Grain Boundaries will lead to the decrease of strength and hardness, while the electrical conductivity will further increase. Pre-deformation before aging can promote precipitation and improve the mechanical properties of the alloy.

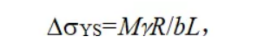

The mechanical properties of the alloy increase with the increase of Ti content, but the electrical conductivity decreases seriously. Although the solution strengthening effect of Ti atom is good, aging treatment is the main method to improve the comprehensive properties of cu-ti alloy. The reinforcement mechanism can be expressed as follows:

In the formula, YS is the yield strength increased by precipitation strengthening, m is the Taylor vector, the face centered cubic material is about 3, the interfacial energy, r is the average diameter of precipitation, b is the burr vector, and l is the average spacing of precipitates on the dislocation slip surface, it can be calculated by the following formula:

In the formula, R is the average diameter of the precipitate, and n is the quantitative density of the precipitate. The aging treatment can not only increase the strength and hardness, but also improve the conductivity of the alloy. It can be seen from Table 1 that the strength of the low content alloy increases several times after aging, but with the increase of Ti content, the strength increase degree decreases after aging, its strength is proportional to the average diameter and number density of the precipitate. However, precipitation growth during aging will reduce the number of precipitation density, so it is necessary to strictly control the aging time to achieve good alloy properties. However, the Ti content of the alloy should be just enough to meet the need of titanium for precipitating phase during peak aging, so that the TI content in the Matrix is the critical value for precipitating, and all the excess titanium atoms form precipitation, cold deformation before aging treatment can promote the formation of precipitates, can be carried out first cold deformation, minimize the TI content in the Matrix, reduce the influence of titanium atoms on the alloy resistance, can effectively improve the overall performance of the alloy. If Ti content is too high, there are a lot of titanium atoms in the matrix during peak aging, which increases the resistance of the alloy, and the resistance of-Cu4Ti phase is higher than that of copper. If the content of TI is too small, the strengthening effect is weak and the mechanical properties of the alloy are poor.

3 The effect of the third component on the properties of cu-ti alloy is lower than that of other copper alloys because of the low conductivity of the binary cu-ti alloy. In order to optimize the properties of cu-ti alloy, a multi-component cu-ti alloy was formed by adding a third component on the basis of the binary cu-ti alloy. The results show that Niti,-ni3ti, And-cu4ti can be obtained by aging treatment, and the electrical conductivity increases, but the strength decreases. The hardness (HV) , electrical conductivity and elastic modulus of Cu-3Ti-1Ni alloy can reach 205 and 10.556 MS/m respectively, while the hardness (HV) and electrical conductivity of Cu-3ti alloy are about 289 and 9.164 MS/M respectively, the hardness (HV) and electrical conductivity of Cu-3ti-3ni alloy can reach 183 and 18.56 MS/M. It was also found that adding Al can produce Alcu2ti, while adding Co can produce TI2CO and Tico, but the increase of electrical conductivity is not obvious, and adding Sn can produce CuTi3Sn5, although its electrical conductivity can reach to 22.62MS/M, its hardness (HV) is only 134.5, the loss of mechanical properties is too much, the practical application value is too small.

In addition to the reaction of Cu-Ti-Fe-Cr alloys with addition of elements, it was found that Cu-Ti-Fe-Cr alloys with addition of Fe and CR would form Cuti, thus reducing the TI content in the matrix and increasing the electrical conductivity of the alloys. The content of Ti in the Matrix can also be reduced by the reaction of Ti with atmosphere in the special atmosphere through diffusion. When cu-ti alloy is aged in hydrogen and deuterium, the dissolved Ti in the alloy reacts with hydrogen to form δ-tih2 and δ-tid2 precipitates, which can effectively reduce the concentration of ti in the alloy substrate, the electrical conductivity of the alloy increased greatly (aging in hydrogen can reach more than 34.80 MS/M, aging in deuterium can reach 27.84 MS/M) and the ductility increased slightly, but the strength decreased.

The precipitation of different elements and titanium is different, the consumption of Matrix and precipitation strengthening effect are also different, the mechanical properties and electrical conductivity of the alloy are different. Therefore, if the electrical conductivity of the alloy is increased by adding a third element to form a strengthening phase, the first consideration is that the third element should be able to react with titanium atoms or with copper and titanium atoms to form a new phase and not react with copper atoms alone. Secondly, the thermodynamic conditions should be taken into account: the formation of a new phase between a new element and a titanium atom is best followed by the formation Of-cu4ti, which can further reduce the content of Ti in the copper matrix and thus increase the electrical conductivity, on the other hand, the content of Ti in the Matrix does not change, the electrical conductivity may not change obviously, and the new strengthening phase can compete with-Cu4Ti atom, if its strengthening effect is not better Than-cu4ti, the mechanical properties of the alloy will also be lost a lot. Finally, because the melting point of titanium is much higher than that of copper, if the melting point of the new element is also very high and a high melting point and coarse primary phase is formed directly with titanium during melting, the solution treatment can not be carried out to eliminate it, which directly affects the properties of the alloy, moreover, the effect of aging strengthening in the later period is also greatly weakened, and the properties of the final alloy are not satisfactory. Therefore, it is necessary to consider the difference between the melting point of precipitates and that of copper, and to predict or simulate the results of melting and casting.

Although some elements can not reduce the TI content in the Matrix, they will affect the microstructure and properties of the alloy. Zr Can inhibit the amplitude modulation decomposition process of the Alloy, restrain the precipitation of discontinuous precipitation, refine grain, and thus improve the strength and hardness of the alloy. Better mechanical properties of CD and CR cu-ti alloys can be obtained by cold deformation and aging. The alloy with low degree of cold deformation will have flake-like discontinuous precipitation, while the alloy with high degree of cold deformation will precipitate globular discontinuous precipitation. CR can also increase the elasticity of the alloy and accelerate the aging process. These elements can not solve the main contradiction of cu-ti alloy, but can optimize the microstructure and influence the microstructure evolution process of the alloy.

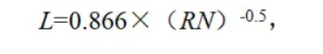

The application of cu-ti alloy has been studied and developed a lot, and Cu-ti alloy has been applied in some fields. Japan already uses the alloy to make sensing elements and spring connectors. Among them, NKT322 and Nkt180 High Strength copper-titanium alloys have been developed by NKT322 and NKT180 for the required properties of the connection plug copper alloys for electronic machines. The composition is shown in Table 2. NKT322 Alloy has high strength and workability, and it is the copper alloy with the best balance between strength and workability in the market at that time, its conductivity is better than that of high beryllium copper alloy. The CU-TI alloy added some elements such as FE, SN, CR and Al is called titanium bronze. The most common titanium bronze alloys are QTI3.5, QTi3.5-0.2 and QTi6-1, as shown in Table 2. The first two alloys have high strength, hardness and elasticity. The electrical conductivity is second only to that of beryllium bronze. They also have excellent wear resistance, corrosion resistance and fatigue resistance, mainly used in electrical switches, relay elastic components, vacuum sockets, various control systems of the spring, plug-in components, bellows, diaphragm, precision small gear and bearings and other products. QTi6-1 alloy has high strength, hardness and elasticity, and its high temperature performance is better than beryllium bronze, but its conductivity is poor, it is mainly used to prepare vibrating plates, diaphragm, contact elastic elements of ultra-high frequency standard, spring of travel switch and so on. Although the electrical conductivity of copper-titanium alloy is low at present, because of its excellent mechanical properties, it has been applied and developed in many fields, in 2012, the grade of copper and copper alloy and its chemical composition revised in our country began to appear the grade of titanium bronze, which indicates that the copper-titanium alloy has been approved commercially in our country and will be widely used in the future.

05 Cu-ti Alloy, the basic problem is that the conductivity of cu-ti alloy is low, and the basic reason is that ti atoms increase the scattering effect of electrons in Cu Matrix, so the conductivity decreases. This is a common property of solid solution, it is difficult to fundamentally solve the problem. So in order to improve the conductivity of cu-Ti alloy, the only effective method is to reduce the content of Ti in the Matrix. At present, the main methods to reduce Ti content in the matrix are precipitation of Cu4ti by aging and the introduction of the third component to form strengthening phase. It is found that the effect of adding different elements and changing the content of elements on the electrical conductivity and mechanical properties of cu-ti alloy is very different. At present, the research of Ternary cu-ti alloy is mostly single component research, few of the third component research and heat treatment process comprehensive influence research. For example, when the hardness (HV) of Cu-3Ti-1Ni alloy decreases by 20, the conductivity of Cu-3Ti-1Ni alloy increases by 8.12 MS/m. A certain amount of rare earth elements can make the conductivity of pure copper reach 62.64 MS/m. If a certain amount of rare earth elements are added to the copper-titanium alloy, it may be possible to increase the electrical conductivity by a small amount. There is still room for further research on the effect of the kinds and compositions of visible elements on cu-ti alloy, so the composition and process of multi-element cu-ti alloy can be optimized and the property limit of multi-element cu-ti alloy can be explored.

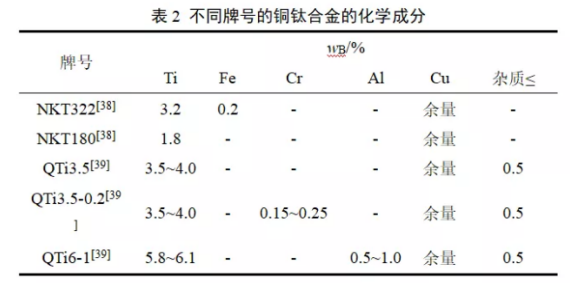

The traditional aging process is solution treatment plus cold deformation followed by peak aging. The hardness (HV) of overaged cu-ti alloy can be increased from 150 to 350, and the conductivity can be decreased from 17.40 to 11.60 MS/M. For the same drawing condition, the hardness (HV) of the peak aged alloy only increased from 260 to 340, but the conductivity decreased from 9.28 to 5.64 MS/M. In contrast, the properties of over-aged cu-ti alloy are much better than those of peak-aged and peak-aged cu-ti alloy. The reason is that Cu3ti is parallel to the drawing direction in the process of overaging, and then its thickness and the space between the sheets are reduced. Finally, the interaction rips into fine fibers, which increases the dislocation density of the alloy, the strength of the alloy increased greatly, and the electrical conductivity decreased slightly. Therefore, the Ternary cu-ti alloy with high conductivity can be overaged to improve the conductivity first, and then the alloy with better comprehensive properties can be obtained by deformation strengthening treatment. Prospect (1) at present, it is mainly through introducing new elements to react with titanium atoms to form precipitation, which can strengthen the second phase particles and improve the conductivity in a small extent. If ultra-fine nano-dispersion precipitation is formed, the number density of the precipitation will be increased greatly, it can also increase the mechanical properties of the alloy by increasing the electrical conductivity first, such as increasing the electrical conductivity after aging, and then increasing the mechanical properties by severe deformation. (2) at present, Cu-ti alloy has high strength and elasticity, which can be improved by adding other elements to optimize its structure and improve its properties.

Source: Special Casting and non-ferrous alloys, vol. 40, no. 6,2020