In this paper, the effect of rare earth on aluminum and aluminum alloy is studied

Release time:2021-12-02Click:983

The application of rare earth in casting aluminum alloy was developed earlier abroad. Although the research and application in this field began in China in the 1960s, it developed very fast, and a lot of work has been done from mechanism research to practical application, and some results have been achieved. With the addition of rare earth elements, the mechanical properties, casting properties and electrical properties of aluminum alloy are greatly improved. In the field of new materials, the rich optical, electrical and magnetic properties of rare earth elements also play an important role in the production of rare earth permanent magnetic materials, rare earth luminescent materials, rare earth hydrogen storage materials.

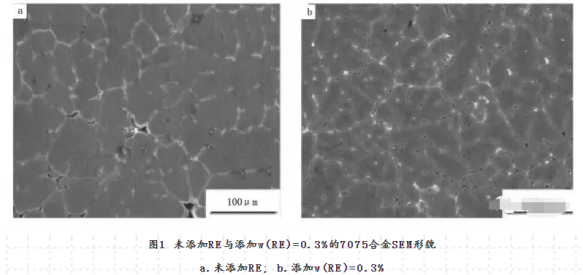

1. Mechanism of rare earth in aluminum and aluminum alloys rare earth has high chemical activity, low potential and special electron layer arrangement, and can interact with almost all elements. LA (LA) , CE (CE) , Y (yttrium) and SC (SC) are commonly used in Al and Al Alloys. Modification agent, nucleating agent and degassing agent are often used in AL liquid to purify melt, improve microstructure and refine grain. 01. The purging effect of rare earth will bring in a lot of gas and oxide inclusions (mainly hydrogen, oxygen and Nitrogen) , which will cause Pinhole, crack and inclusion in the casting (see fig. 1A) and reduce the strength of aluminum alloy. The purification effect of rare earth is to reduce the hydrogen content in liquid aluminum, the porosity and porosity (see fig. 1B) , and the inclusion and harmful elements. The main reason is that rare earth has a strong affinity with hydrogen, can absorb and dissolve hydrogen in large amount, and form stable compounds, which can not aggregate into bubbles, so that the hydrogen content and porosity of aluminum are obviously reduced, in the smelting process, most of them are removed in the form of slag, so as to achieve the goal of purifying liquid aluminum. The results show that rare earth can reduce the content of hydrogen, oxygen and sulfur in aluminum and its alloys. Adding 0.1% ~ 0.3% RE into the molten aluminum is helpful to remove harmful impurities, refine impurities or change their appearance, in addition, RE is mixed with harmful impurities at low melting point to form binary compounds such as RES, REAs and REPB. These compounds have the characteristics of high melting point, low density and stable chemical property, thus purifying the liquid aluminum; the remaining fine particles become heterogeneous nuclei of aluminum to refine the grains.

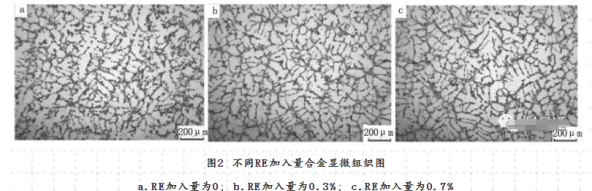

02. The modification of rare earth mainly involves refinement of grains and Dendrites, suppression of the appearance of Coarse T2 phase, elimination of coarse massive phase and formation of globular phase, the strip-like and fragment-like compounds at grain boundaries are obviously reduced (see Fig. 2) . In general, the radius of rare earth atom is larger than that of aluminum atom, and the properties of rare earth are more active. The surface defects of alloy phase can be easily filled by melting in aluminum liquid, which reduces the surface tension of the new-old two-phase interface and increases the growth rate of crystal nucleus At the same time, it can form a surface active film between the grain and the melt liquid, prevent the grain from growing and refine the alloy structure (see figure 2B) .

When rare earth elements were added, α (AL) phase grains began to become smaller, which played a role in grain refinement. The original coarse dendriform α (AL) phase changed into smaller Rosette or rod shape. When the rare earth content was 0.3% , the crystal grains of α (Al) phase were the smallest, with the increase of rare earth content, the grain size becomes larger. The experiments show that there is a certain latent period of rare earth metamorphism, and only when the METAMORPHISM is maintained at high temperature for a certain period of time, can the rare earth play the most important role in metamorphism. In addition, the structure of the alloy is refined by the increase of nucleation number of the compound formed by Al and re during the metal crystallization. The results show that rare earth has a good modification effect on aluminum alloy. (2) microalloying of re re re mainly exists in AL and AL alloys in three forms: solid solution in Matrix α (AL) , segregation in phase boundary, grain boundary and dendrite boundary, solid solution in compound or in compound form. The strengthening effect of rare earth in aluminum alloys mainly includes fine grain strengthening, limited solid solution strengthening and second phase strengthening of rare earth compounds. When RE content is less than 0.1% , the effect of RE is mainly fine grain strengthening and limited solid solution strengthening, and when RE content is 0.25% ~ 0.30% , a large number of spherical or short rod-shaped intermetallic compounds are formed between RE and AL, which are distributed in grains or grain boundaries, and a large number of dislocations and fine grain spheroidizing structures and dispersed rare earth compounds occur.

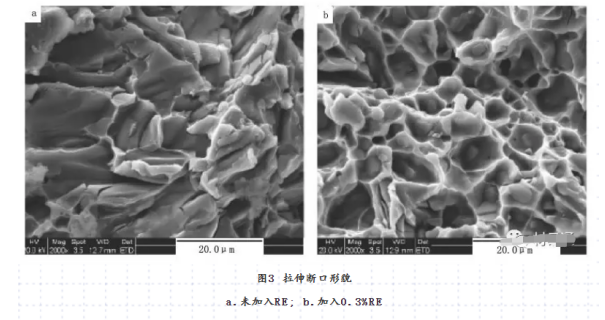

Effect of rare earth on properties of aluminum and its alloys 01. The effect of Rare Earth on the comprehensive mechanical properties of the alloy proper addition of rare earth can improve the comprehensive mechanical properties of the alloy such as strength, hardness, elongation, fracture toughness and wear resistance. The addition of 0.3% re in cast aluminum ZL10 alloy increased the σb from 205.9 MPA to 274 MPA, HB from 80 to 108, the addition of 0.42% SC in 7005 alloy increased the σb from 314 MPA to 414 MPA, the Σ0.2 from 282 MPA to 378 MPA, and the plasticity from 6.8% to 10.1% , the superplasticity of al-6mg-0.5 MN alloy was increased from 430% to 800% to 1000% when 0.14% ~ 0.64% La was added into the alloy, it is found that the yield strength and ultimate tensile strength of the alloy can be greatly improved by adding proper amount of SC. Fig. 3 is the SEM appearance of tensile fracture surface of Al-Si7-Mg0.8 alloy, which shows that the typical brittle cleavage fracture without RE, and the obvious dimple structure appears in the fracture surface after 0.3% RE addition, which shows that Al-Si7-Mg0.8 alloy has good toughness and ductility.

02. The effect of rare earth on the high temperature properties of aluminum alloy adding certain amount of rare earth can effectively improve the high temperature oxidation resistance of aluminum alloy. By adding 1% ~ 1.5% mixed rare earth into the cast Al-Si eutectic alloy, the high temperature strength increased by 33% , the high temperature endurance strength (300 °C, 1000 hours) increased by 44% , and the wear resistance and high temperature stability increased remarkably The addition of La, CE, Y and mixed rare earth in Al-Cu cast alloys can improve the high temperature properties of the alloys, and the al-8.4% fe-3.4% Ce alloy with rapid solidification can work for a long time under 400 °C, by adding Sc into Al-Mg-Si Alloy, the AL3SC particles which are not coarsening and coincident with the Matrix can be formed at high temperature, and the grain boundaries of the alloy can be nailed to keep the non-recrystallized structure in the annealing process, the high temperature properties of the alloy are greatly improved.

The effect of Rare Earth on the optical properties of the alloy adding rare earth into the aluminum alloy can change the structure of the oxide film on the surface and make the surface more bright and beautiful. When 0.12% ~ 0.25% RE is added to Al-Mg cast aluminum alloy, the RE-6063 profile with oxidation coloring has a high reflectivity of 92% , and when 0.1% ~ 0.3% RE is added to Al-Mg cast aluminum alloy, for the best Surface finish and gloss durability.

04. The influence of RE on the electrical properties of Al-Mg-Si alloys the addition of RE to Al-Mg-Si alloys is harmful to the electrical conductivity of Al-Mg-Si alloys, but the addition of RE to Al-Mg-Si alloys can improve the electrical conductivity to some extent. The experimental results show that the electrical conductivity increases by 2% ~ 3% when 0.2% RE is added to aluminum. Adding a small amount of yttrium-rich rare earth to Al-Zr alloy can improve the electrical conductivity of the alloy, which has been adopted by most wire factories in China, the unit volume capacity is increased by 5 times, the weight is reduced by 47% , and the volume of the capacitor is reduced significantly. 05. The effect of rare earth on the corrosion resistance of alloy is easy to be destroyed by corrosion, crevice corrosion, stress corrosion and corrosion fatigue in some service environments, especially in the presence of chloride ion. In order to improve the corrosion resistance of Aluminum Alloy, many researches have been carried out, and it is found that adding proper amount of rare earth into aluminum alloy can effectively improve the corrosion resistance of aluminum alloy. The results show that the corrosion resistance of aluminum can be improved by adding different amount of rare earth (0.1% ~ 0.5%) into the aluminum and immersing it in saline water and artificial sea water for 3 years, the corrosion resistance of 2024 alloy is 24% and 32% higher than that of aluminum in saline water and artificial sea water, respectively, the results show that the surface electrode potential of Al Alloy is uniform, and the corrosion resistance of Al Alloy to intergranular corrosion and stress corrosion is improved, the corrosion resistance of Al Alloy to ocean corrosion is improved by adding La into high MG AL alloy, and 1.5% ~ 2.5% ND IN AL alloy, the invention can improve the high temperature performance, air tightness and corrosion resistance of the alloy, and is widely used as aerospace materials.

5.Preparation of rare earth aluminum alloys rare earth is usually added in the form of micronutrient in aluminum alloys and other alloys. Rare Earth has high chemical activity, high melting point, and is easy to be oxidized and burned at high temperature, it is difficult for the preparation and application of rare earth aluminum alloy. In the long-term Experiment Research, people continuously explore the preparation method of rare earth aluminum alloy. At present, the main production methods of rare earth aluminum alloy are mixed fusion, Molten Salt electrolysis and aluminothermic reduction.

01. The mixed melting method is to add the rare earth or mixed rare earth metals to the high temperature liquid aluminum to make the master alloy or the application alloy.

02. The process of Molten Salt electrolysis is to add rare earth oxide or rare earth salt into the industrial aluminum electrolytic cell and electrolyze with alumina to make rare earth aluminum alloy. MOLTEN SALT electrolysis has developed rapidly in China. Generally, there are two ways, namely, liquid cathode method and electrolytic eutectoid method. At present, it has developed to the point where rare earth compounds can be directly added to industrial aluminum electrolytic cells, rare earth aluminum alloy produced by electrolysis of chloride melt with eutectoid process. 03. Aluminum can be used as reductant to prepare rare earth aluminum alloy because of its strong reducibility and the formation of many intermetallic compounds with rare earth. The main chemical reactions are as follows: RE2O3 + 6Al →2REAl2 + Al2O3 in which rare earth raw materials can be enriched with rare earth oxides or rare earth slag;. In recent years, researchers have developed a new thermite reduction method at a lower temperature (780 °c) , in which the thermite is reduced at a lower temperature (780 °c) and the thermite is reduced at a lower temperature (780 °c) , the aluminothermic reduction reaction in the system of sodium fluoride and sodium chloride avoids the problem of high temperature.

6.Application progress of rare earth aluminum alloy 01. The application of rare earth aluminum alloy in electric power industry can be used to manufacture electric cable, overhead transmission line, wire core, slip connection and special purpose fine conductor because of its advantages of good conductivity, high current carrying capacity, high strength, wear resistance, easy processing and long service life. The addition of trace RE in Al-Si alloy system can improve the electrical conductivity, because silicon is the impurity element with high content in Al-Si alloy has a great influence on the electrical properties, the electrical properties of aluminum can be effectively improved by adding a proper amount of rare earth, and the electrical properties of aluminum can be effectively improved by adding a small amount of yttrium or yttrium-rich mixed rare earth into the conductor of heat-resistant aluminum alloy, rare earths can improve the tensile strength, heat resistance and corrosion resistance of aluminum alloy systems, and cables and wires made of rare earths and aluminum alloys can increase the span of cable towers, and extend the service life of the cable.

02. The most widely used rare earth aluminum alloy in the construction industry is 6063 aluminum alloy. Adding 0.15% ~ 0.25% rare earth can obviously improve the as-cast structure and processing structure, can Improve extrusion performance, heat treatment effect, mechanical properties, corrosion resistance, surface treatment performance and tone. The results show that rare earth elements in 6063 aluminum alloy are mainly distributed in α-Al neutral phase boundary, grain boundary and Dendrite, the undissolved eutectic size and the dimple size in the dimple area are reduced obviously, the distribution is uniform, the density is increased, and the properties of the alloy are improved in different degrees, such as the strength of the profile is increased by more than 20% , the elongation is increased by 50% , the thickness of oxide film increases by 5% ~ 8% , and the coloring property increases by 3% . Therefore, RE-6063 alloy building profiles have been widely used.

03. The application of rare earth aluminum alloy in daily-used aluminum products can improve the mechanical properties, deep-drawing property and corrosion resistance of aluminum alloys such as pure aluminum and Al-Mg series. The corrosion resistance of daily necessities such as aluminum pot, aluminum pot, aluminum plate, aluminum lunch box, aluminum furniture bracket, aluminum bicycle and home appliance parts made of Al-Mg-RE alloy is more than 2 times higher than that of the aluminum alloy products without rare earth added, weight reduced by 10% ~ 15% , yield increased by 10% ~ 20% , production cost reduced by 10% ~ 15% , and better deep drawing and deep processing performance. At present, the rare earth aluminum alloy daily necessities have been widely used, the product increases greatly, the best-selling domestic and foreign markets.

04. The application of re-al alloy in other fields can obviously improve the machinability of the most used al-si cast alloy by adding a few thousandths of re, there are a variety of brands of products for aircraft, ships, cars, diesel engines, motorcycles and armored vehicles (Piston, gearbox, cylinders and instruments and other parts) and so on. It is found that SC is the most effective element for optimizing the microstructure and properties of aluminum alloy, and it has strong effects on dispersion strengthening, fine grain strengthening, solid solution strengthening and micro-alloy strengthening, it can improve the strength, hardness, plasticity, toughness, corrosion resistance and heat resistance of the alloy. SC-AL series alloys have been used in aerospace, naval ships, high-speed trains, light vehicles and other high-tech industries. C557AL-MG-ZR-SC SC scandium aluminum alloy developed by NASA has been used in airframe and airframe with high strength and high and low temperature stability 0146AL-CU-LI-SC alloys developed in Russia have been used in cryogenic fuel tanks of spacecraft.

Source: Caitong