Haowen, the effect of the state of raw material on the technological properties of continuous extrusion of brass alloy, from the mechanical properties of raw material and products of brass alloy, microstructure and so on

Release time:2021-05-26Click:1814

ABSTRACT: The microstructure of annealed and drawn H62 brass alloy after continuous extrusion was compared and analyzed. The results show that the tensile strength and elongation of annealed raw materials are lower than those of drawing raw materials, and their plastic deformation ability is better than that of drawing raw materials, the samples with uniform grain size were obtained by continuous extrusion process from annealed and drawn materials, and the microstructure and properties of the products were improved by dynamic recrystallization, after continuous extrusion, the microstructure and properties of the samples are close to each other.

Key words: Brass Alloy; Continuous extrusion; microstructure;

Mechanical Properties classification: TG379 DOCUMENT ID: a Article Id: 1001-3814(2011)19-0110-02

The continuous extrusion technology effectively utilizes the mechanical friction between the extrusion cavity and the blank, and transforms it into the power needed for continuous extrusion, which reduces the energy consumed by the traditional extrusion technology due to overcoming the harmful friction of the extrusion cylinder wall, reduces the energy consumption of conventional extrusion by about 30% . Compared with the traditional process, the continuous extrusion process effectively reduces the wire drawing process pickling, bright annealing and other processes, greatly reducing the processing costs. At present, the main brass wires used in production are flat wire and round wire. There are two kinds of brass alloy raw mode of production for continuous extrusion: one is produced by up drawing continuous casting-drawing stripping process (drawing raw material) , the other is produced by adding annealing process after drawing (annealing raw material) . The first raw material can be directly used in the continuous extrusion process after drawing, which can reduce the process links, and the second raw material can be obtained by annealing process, which can effectively reduce the deformation resistance of brass in the continuous extrusion process. The properties and forming characteristics of H62 brass have been studied in reference [1-5] . In this paper, the microstructure and mechanical properties of H62 drawing raw material and annealed raw material for continuous extrusion were compared, and the relationship between microstructure and mechanical properties of brass alloy raw material and product was analyzed, it provides theoretical guidance for continuous extrusion process.

1. Experimental materials and methods

The raw material of H62 was produced by up-drawing continuous casting-drawing stripping process, and the raw material of H62 was treated by annealing process. The annealing process was as follows: heating the raw material of drawing to 570 °C and holding for 3 hours, furnace Cooling 1H. Two kinds of raw materials were tested on Tlj250 continuous extrusion machine, and the samples of 1.6 mm 6.4 mm drawing raw materials and annealing raw materials were obtained by water cooling. TLJ250 continuous extrusion machine extrusion wheel diameter 250 mm, wheel groove width 8 mm, die 1.6 mm 6.4 mm flat wire die. The drawing raw material and its sample, the annealed raw material and its sample were made into metallographic specimen, and the samples were grinded, polished and corroded. FECL3(5g) + HCL (25mL) + H2o (50mL) solution was selected as the corrosion agent for the raw material and product, the mechanical properties of raw materials and products were tested respectively.

2. Analysis and discussion

2.1 microstructure of drawing stock and annealing stock

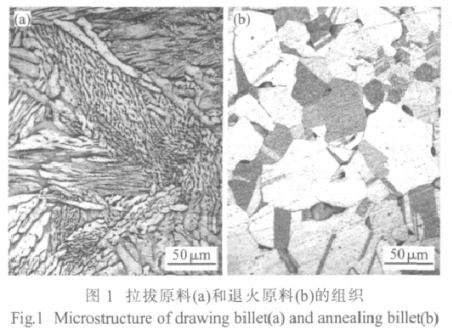

Fig. 1 is the microstructure of drawing material and annealing material. The microstructure of the drawing raw material produced by up-casting-drawing peeling process is coarse as-cast columnar crystal structure, and a lot of black acicular phase is retained in the white phase The microstructure of the annealed raw material is equiaxed crystal formed by annealing process, and annealing twins appear in the microstructure, in which the black spots are phase and the rest are phase, and the phase content in the microstructure is less.

According to the alloy phase diagram, under equilibrium state, H62 brass alloy should be completely transformed into phase [6] below 500 °C. However, in actual production, the cooling rate is very fast, the phase-to-phase transformation can not be fully carried out, will retain part of the phase in the organization, the faster the cooling rate, the more phases. Because of the long holding time and slow cooling speed, the content of phase in the microstructure of annealed material is less.

2.2 The microstructure of the sample is obtained by continuous extrusion of two kinds of raw materials. The sample is produced by continuous extrusion of raw materials, the microstructure of the center and edge of the extrusion product is shown in Fig. 2. As can be seen, the average grain size of edge microstructure

The grain size of the edge structure is smaller than that of the center, and the phase content in the edge structure increases. The annealed raw material continuous extrusion product is the product obtained by continuous extrusion process of annealed raw material. The microstructure of the annealed raw material continuous extrusion product center and edge is shown in Fig. 3. It can be seen that in the microstructure, white grains are phase and fine black grains are phase. The average grain size of edge microstructure is 12 m, the average grain size of central microstructure is 20 m, and the grain size of edge microstructure is smaller than that of central microstructure.

To sum up, the products obtained by continuous extrusion process of drawing and annealing materials have certain similarity in microstructure, the common characteristics are: The microstructure after continuous extrusion is recrystallized structure, showing fine equiaxed crystal. After continuous extrusion, the grains are refined obviously. The average grain size of the central structure is larger than that of the edge structure. In the process of continuous extrusion, the edge part is subjected to severe shear friction, and the grain size of the edge part is smaller than that of the center part because of the cooling rate.

2.3 mechanical properties of raw materials and products of brass alloy

The tensile strength and elongation of the raw material and sample of the brass alloy under the two conditions are compared as shown in Fig. 4. As you can see from the tensile strength curve,

The tensile strength of the annealed raw material is higher than that of the drawn raw material, but the tensile strength is lower. After continuous extrusion, the tensile strength of the two samples is similar. In the elongation curve, the elongation of the tensile material is lower than that of the annealed material, and the elongation of the two samples is close after continuous extrusion. To sum up, the state of raw material has little influence on continuous extrusion process. After continuous extrusion of raw materials in different states, products with better comprehensive mechanical properties can be obtained.

3. Conclusion

(1) after continuous extrusion, dynamic recrystallization of H62 alloy in drawing state and annealing state occurs, and samples with good comprehensive mechanical properties are obtained.

(2) in the structure of annealed raw material, the content of phase increases, the plasticity of raw material is improved, and the continuous extrusion is carried out, the drawing raw material reduces the continuous extrusion process, and the structure contains a lot of phase, the hardness is higher and the plasticity is lower, it can be solved by preheating the raw material.

(3) after continuous extrusion, the grains of the two products are refined obviously. The refined grains are beneficial to improving the strength and plasticity of the metal, and the refined grains can also improve the surface quality of materials, the fine and uniform structure is very important to guarantee the plasticity of the material and the surface quality of the finished product.

Source: Chinanews.com by Li Chunhai