Research progress on corrosion fatigue of aluminum alloys in aerospace industry

Release time:2022-02-18Click:971

As a light alloy with high strength and toughness, good corrosion resistance, good workability and welding performance, aluminum alloy is widely used in the field of aeronautics and Astronautics, as the preferred material for aircraft skins and frames and for the main structure of spacecraft, the main function is to bear and transmit loads. At present, most aircraft in China have the phenomenon of “Less flying, more stopping”, in which more than 95% of the calendar life of military aircraft is on the ground, and the corrosion of the ground is much higher than the air fatigue, is a major factor affecting the calendar life of military aircraft. Compared with military aircraft, civilian aircraft can spend up to 60% of their time on the ground. Taking X7 and X8 aircraft as an example, their time on the ground accounts for more than 95% of their time in service. Corrosion has a serious impact on the life of the aircraft.When the tiny corrosion damage caused by high altitude flight is ignored, it is considered that the corrosion damage is dominant when the aircraft is parked at the airport, and the fatigue damage is dominant when the aircraft is flying at high altitude, the service process is close to “Corrosion + fatigue + corrosion + fatigue + ...”alternating process. During the first service of the spacecraft, the contact corrosion environment of the ground test and assembly process is short, and the corrosion of the aluminum alloy hardly occurs in the space environment, in addition to the fatigue problem caused by alternating load, it is also faced with a number of ground maintenance, testing, assembly process by corrosion. Unlike the corrosion fatigue of aircraft, there is no high altitude corrosion during the service of reusable spacecraft, which is more in line with the “Corrosion-fatigue”alternating process.

With the development of aerospace industry, Aluminum Alloys with high strength 2xxx series (2A12,2024,2219,2090, etc.) and Super Strength 7xxx series (7050,7075,7A04,7055, etc.) are the most widely used and widely used alloys in aerospace industry, it is mainly used in wing, fuselage skin, upper and lower flange of wing beam, pressure chamber and fairing, etc. . At the same time, some 5xxx series (5A06,5456,5086,5B70, etc.) anti-rust aluminum alloy, because of good weldability, fatigue and resistance to Marine atmospheric corrosion, it is commonly used in aircraft engines, gearboxes, support structures and integral wallboards of spacecraft, as well as in small quantities of 6xxx series (6A02,6013, etc.) and 8xxx series (8091, etc.) aluminium alloys for the manufacture of aircraft engine parts. The corrosion is mainly concentrated in the fuselage skin, the wing front beam abdomen, the wing beam upper and lower flange, the fuselage long truss external skin rivet, the tail frame and so on, these are also the corrosion fatigue failure danger spot [5] .

Corrosion fatigue failure is a common form of failure of components under corrosion environment and interaction of alternating load. It is not simply a superposition of corrosion and fatigue effects, but a synergy between corrosion factors and fatigue stresses that is greater than any one of them alone [13-15]. In recent decades, a large number of corrosion fatigue tests have been carried out by scholars at home and abroad, which have made outstanding contributions to the investigation of corrosion fatigue mechanism, influencing factors of corrosion fatigue and fatigue life variation of aerospace aluminum alloys. In recent years, the unique characteristics of fatigue life of aluminum alloy under cyclic corrosion fatigue have been found. Based on the corrosion fatigue mechanism of aluminum alloy, the main corrosion fatigue test techniques are introduced, and the main factors affecting corrosion fatigue and the characteristics of fatigue life under alternating corrosion fatigue are analyzed, the development trend of corrosion fatigue of aluminum alloy was prospected.

1 corrosion fatigue mechanism of aluminum alloy 1.1 corrosion fatigue crack initiation mechanism in corrosion environment, Fatigue crack initiation is a complex process, which is closely related to corrosion environment, mechanical factors, material factors, etc. , the corrosion environment plays an important role in the corrosion fatigue, and the corrosion fatigue mechanism is mainly composed of the following factors:

1) local corrosion theory. Crack initiation usually occurs under the synergistic action of corrosion environment and cyclic loading, and is caused by stress concentration caused by corrosion pits and local defects on the surface of materials. At present, it is considered that pitting corrosion plays an important role in the fatigue crack initiation process of aluminum alloy, but the effect of pitting corrosion on the fatigue life of aluminum alloy is not obvious in the high stress cycling region, but it is obvious in the low stress region. This theory is applicable to the aluminum alloy materials which are sensitive to pitting corrosion and have local corrosion, which has some limitations, and the aluminum alloy materials which are not sensitive to pitting corrosion can also have corrosion fatigue process. 2) ANODIC dissolution-membrane rupture theory. The surface passivation film of Aluminum Alloy was broken under the action of external force. The primary battery is composed of oxide film protecting part and local bare part in corrosive environment. The bare part is dissolved continuously as anode until the oxide film is repaired, and then the process of Membrane rupture-anodic dissolution-membrane repair is repeated continuously, which leads to fatigue crack initiation. 3) surface adsorption theory. The surface energy, surface strength and mechanical properties of Aluminum Alloy in corrosive environment are decreased by adsorption of active materials. At this point by the role of cyclic stress, easy to cause fatigue damage. The hydrogen atoms on the surface of aluminum alloy will diffuse to the interior and destroy the hydrogen embrittlement.

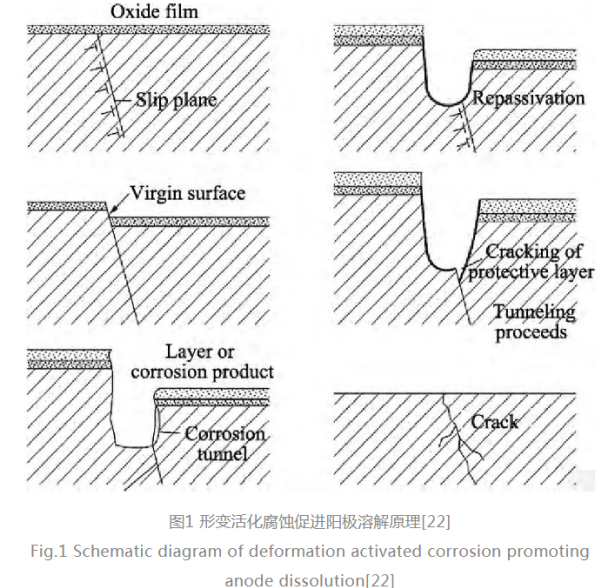

1.2 The mechanism of corrosion fatigue crack growth in the process of corrosion fatigue, taking the smooth specimen as an example, the crack initiation life only accounts for 10% of the total corrosion fatigue life, while the crack growth life accounts for 90% . So the service life of corrosion fatigue specimen is mainly corrosion fatigue extended life. The mechanism of corrosion fatigue propagation is partially similar to that of initiation, there are three main corrosion fatigue crack propagation theories: 1) mechanism of deformation activation promoting anodic dissolution; 2) mechanism of hydrogen embrittlement; 3) surface energy drop model. In the early stage, it was considered that the corrosion fatigue crack growth of aluminum alloy was mainly based on the anodic dissolution theory. The mechanism of anodic dissolution explained the local anodic dissolution of the periodically exposed crack tip, which would accelerate the corrosion fatigue crack growth, as shown in Fig. 1. The mechanism of anodic dissolution depends on the rupture of the protective film at the crack tip and the subsequent re-passivation of freshly exposed metal surfaces. The corrosion fatigue crack growth rate will be controlled by the anodic dissolution rate, the repassivation rate, the oxide film rupture rate and the mass transfer rate from reactants to the solution surface.

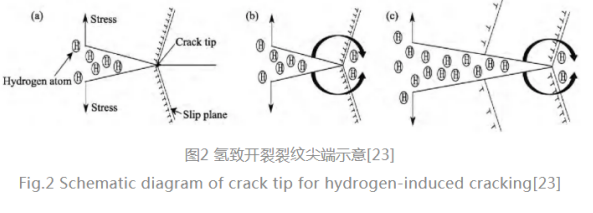

It was found that the anodic dissolution of aluminum in the Matrix would produce hydrogen. Fig. 2 shows the process of hydrogen-induced crack growth under stress: A) the stress concentration at the crack tip causes dislocation movement; b) the interaction of hydrogen with the dislocation and the diffusion of hydrogen atoms increase the hydrogen concentration at the crack tip under stress; c) when the hydrogen concentration at the crack tip reaches a critical value, hydrogen embrittlement occurs, causing the crack at the crack tip to propagate forward and then repeat the process. At present, the mechanism of hydrogen embrittlement is more and more preferred for the propagation of corrosion fatigue crack, but how the hydrogen diffuses into the material and causes the hydrogen embrittlement failure needs to be investigated from the microscopic mechanism of hydrogen induced cracking.

The surface energy drop model is similar to the adsorption theory in the mechanism of crack initiation. Both the model and the mechanism of hydrogen embrittlement are environmental factors that lead to the change of fatigue properties of materials, but the surface energy drop model has a small application range, the mechanism of the action of the adsorbed active particles on the material is also unclear. The mechanism of initiation and propagation of corrosion fatigue crack is closely related to the corrosion environment, and the initiation of crack is greatly influenced by pitting in local corrosion. The mechanism of anodic dissolution and the theory of hydrogen-induced cracking have great influence on the crack propagation. In anodic dissolution-dominated corrosion fatigue, crack propagation is a process of alternating stress and chemical reaction dissolution of material surface in corrosive medium. Hydrogen embrittlement occurs in the Matrix due to the diffusion of hydrogen atoms into the Matrix during hydrogen-induced corrosion fatigue, and brittle cracks occur and propagate under alternating stress. The two mechanisms do not exist independently, but in a state of coexistence and competition between the two. At the same time, it is found that the mechanism of corrosion fatigue crack growth does not exist alone, but mainly depends on one mechanism and many mechanisms exist together.

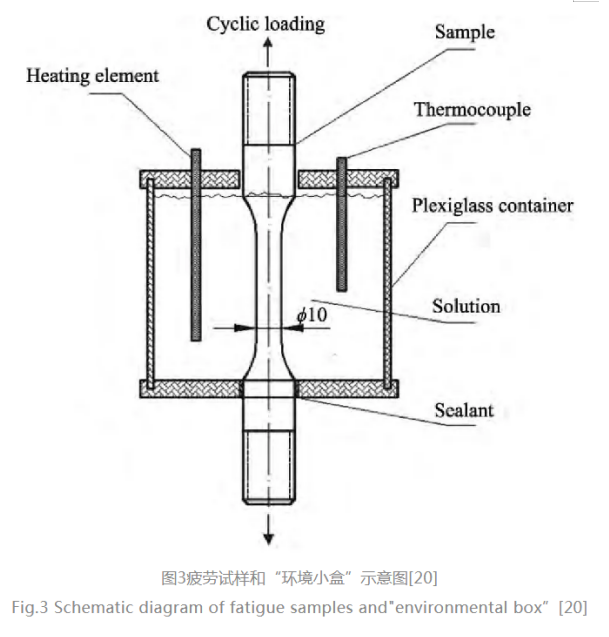

Due to the long failure process of the material in the real service environment, it is difficult to carry out the fatigue research in the real corrosion environment. Therefore, it is necessary to establish accelerated corrosion fatigue test methods under laboratory conditions, including the equivalent of actual service environment and laboratory corrosion environment and the simulation of corrosion fatigue environment. 2.1 corrosion fatigue environment simulation currently, the corrosion fatigue is simulated in three coupling forms: 1) the corrosion fatigue synchronous experimental technique, that is, the corrosion environment and the alternating load act at the same time until the corrosion occurs, and the test data obtained are the result of the synergistic effect of fatigue and environmental factors. As shown in Fig. 3, it is necessary to make a corrosion chamber on the fatigue testing machine to establish the corrosion fatigue environment conditions so as to realize the fatigue durability test and crack detection under corrosive medium. The effect of Ph variation on the corrosion fatigue crack growth of LY12CZ aluminum alloy was investigated by means of “Environmental box”. It was found that the anodic dissolution mechanism was dominant in the crack growth in neutral environment, but with the decrease of Ph, the dominant effect was gradually replaced by hydrogen evolution reaction. The fatigue life of two aviation aluminum alloys (2E12-T3,7050-T7451) under 3.5% NACL corrosion fatigue was investigated by Wang chi-quan et Al. [27] .

2) pre-corrosion Fatigue Test Technology, that is, first corrosion nucleation, and then increase the fatigue load, until fatigue failure. According to the data [5-7] , the fatigue loading time of Chinese military aircraft is less than 5% of the calendar time, and more than 95% of the time is grounded. For this kind of aircraft, the model of ground corrosion first and air fatigue later is usually used, that is, the pre-corrosion fatigue test technique is adopted. However, the corrosion fatigue alternation should be considered in the case of more coastal flight missions and longer fatigue loading time. It has been found that pre-corrosion damage can accelerate the fatigue failure process. Huang Yanfeng et AL [28] studied the corrosion pit characteristics and fatigue crack propagation of 7075-T6 aluminum alloy under different pre-corrosion time. With the increase of corrosion time, the surface size of the corrosion pit increases and usually converges with the adjacent corrosion pit to form a pit cluster. The pre-corrosion fatigue test of 2024-T62 aluminum alloy was carried out by Liu et Al. . It was found that the pre-corrosion had a significant effect on the fatigue S-N curve and fatigue crack initiation behavior, but had no effect on the crack propagation behavior. Xu Liang et Al [30] pointed out that the crack initiation life after pre-corrosion only accounts for less than 20% of the total life due to pre-corrosion damage, and the fatigue life decreases sharply. Sankaran et AL [31] precorroded 7075-T6 aluminum alloy by circulating salt spray method, it was found that pitting corrosion would reduce the fatigue life to 1/6 ~ 1/8 of the original.

In the study of corrosion fatigue of high strength aluminum alloy for aircraft, there is also the study of prediction of corrosion fatigue life based on finite element simulation. The fatigue life of pre-corroded wing was studied by combining corrosion test with finite element method, and the fatigue life of pre-corroded Wing was evaluated accurately. CERIT ET AL [33] based on the finite element analysis, the stress distribution at the semi-elliptic corrosion point is studied. It is found that the notch aspect ratio (A/2C) is the main parameter affecting the stress concentration factor (SCF) , it is also found that the stress concentration at the local (pitting) corrosion site of high strength aluminum alloy is the potential cause of fatigue crack nucleation. Hu Ping et al used the elastoplastic damage constitutive equation and the elastoplastic damage evolution model to evaluate the fatigue damage, proposed a continuum damage mechanics method, and improved the dent evolution model, the corrosion fatigue life of aluminum alloy was effectively predicted. [35] Lu Shengli et Al. [35] used AFGROW software to simulate the effects of corrosion damage and the depth of the corrosion pit on the residual fatigue life of the specimen, and predicted the stress and the nucleation site of the crack caused by the corrosion pit, an effective and reliable engineering method for predicting the fatigue life of corroded specimens was established. At present, the experimental technique of pre-corrosion fatigue is widely used in the research of aircraft aluminum alloy corrosion fatigue.

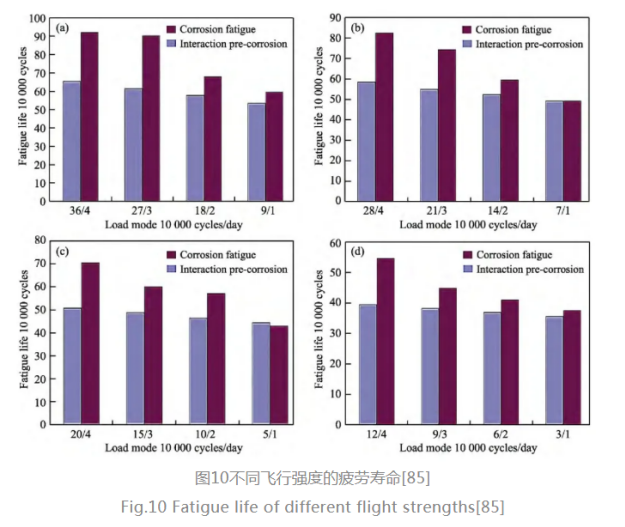

3) the technique of corrosion-fatigue alternating test is the interactive test of environmental corrosion and load fatigue of materials under certain cycle. The interaction between corrosion and fatigue will lead to the change of fatigue properties of materials. At present, it is generally believed by scholars that the corrosion damage is dominant when the aircraft is parked in the coastal airports, and the damage caused by the corrosive environment at high altitude is negligible when the aircraft is in the air service, and the fatigue damage is dominant. It is concluded that for military aircraft with high flying missions and civilian aircraft with frequent start-stop operations in coastal environment, the service process is subjected to corrosion and fatigue alternation, namely “Corrosion + fatigue + corrosion + fatigue + fatigue +”cyclic process. The first alternation process can be equal to the pre-corrosion fatigue process, but the effect of corrosion damage is less than that of pre-corrosion in general. This alternate form is also consistent with the corrosion fatigue of reusable spacecraft in the course of multiple space shuttle and ground repair. In order to study the effect of alternate order of corrosion and fatigue on the fatigue life of aluminum alloy, the fatigue life of LY12CZ aluminum alloy under “Corrosion-fatigue”test and “Fatigue-corrosion-fatigue”test was compared. At present, in the study of coupling forms of corrosion fatigue of aluminum alloy, the precorrosion fatigue is in the majority, especially for the influence of pitting corrosion and corrosion pit on crack initiation, propagation and fatigue life. Under complex interaction, the mechanism of crack development under multi-influence factors is not clear, and there is no unified conclusion on the rule of fatigue life.

2.2 Real, reliable and intuitionistic corrosion data can be obtained under the equivalent natural environment exposure test of corrosive environment, but it is limited by the long test cycle, high cost and difficult to realize. In order to obtain accurate and fast corrosion fatigue test data, the research of accelerated corrosion method in laboratory is of great significance. The corrosion effect of several months or even years in the actual service environment can be achieved in a short time, which requires the compilation of accelerated corrosion equivalent environmental spectra, the specific principles are as follows [38-39] : 1) the principle of equivalence of local corrosion damage at key fatigue locations must be followed; 2) the corrosion damage forms, characteristics and composition of corrosion products at key locations of the actual structure in the actual service environment must be reproduced; 3) the accelerated equivalent relationship between the corrosion time and the actual corrosion time is determined, that is, the ratio of the actual corrosion time to the laboratory accelerated corrosion time corresponding to the same corrosion depth under the same reliability condition; 4) the accelerated corrosion equivalent environmental spectrum should be simplified as far as possible to ensure that the corrosion test environment is easy to realize. Accelerated corrosion equivalent relationship is the “Link”between laboratory environment and actual environment, but the determination of equivalent corrosion time is still a technical problem at home and abroad. At present, the methods to establish the equivalent relation of accelerated corrosion are: 1) equivalent reduction method based on the criterion of IC equivalence of metal corrosion current; 2) fatigue strength (life) comparison method based on the equal corrosion damage;

3 influence factor of corrosion fatigue 3.1 different materials have different corrosion resistance because of their different composition, structure and heat treatment state. It is found that when the MG content of 5xxx Al-Mg alloy is more than 3.5% , the β phase (Al3Mg2) precipitates along the grain boundary as the anode preferentially dissolves, and the tendency of intergranular corrosion and stress corrosion corrosion occurs easily. At the same time, the presence of Zn, FE, Cu, Sn and other elements in aluminum alloys will reduce the corrosion resistance of the alloys. The 7xxx series alloys (al-Zn-mg) without Cu elements have better corrosion resistance. When the SN content is 0.03% in Al-Mg-Si alloy A6061, the grain boundaries can be refined and the corrosion resistance can be improved. However, when the SN content is high (0.4%) , the anode MG2(Si, Sn) phase will be formed and serious corrosion will occur. However, with the addition of SC and Zr, the grain refinement and recrystallization were promoted, and the intergranular corrosion and exfoliation corrosion were inhibited, however, the effect of SC and Zr microalloying on corrosion fatigue properties needs to be further studied.

The 3xxx and 5xxx series of heat-treatable strengthened alloys generally have higher corrosion resistance than the 2xxx and 7xxx series of heat-treatable strengthened alloys. The presence of AL2CU MG and Al2Cu metal compounds in 2024 Aluminium Alloy can improve their mechanical properties, but increase the possibility of local corrosion, mainly due to the sensitivity of intergranular corrosion, artificial aging or surface treatment is usually required to improve corrosion resistance. Moutarlier et Al. [46] found that the corrosion resistance of 2024 Aluminium Alloy in nacl solution was significantly improved after anodic oxidation. Gadpale et Al. [47] found that 2014 aluminum alloy has higher corrosion resistance at lower aging temperature and shorter aging time, which is due to the homogeneous distribution of precipitates in the matrix. Niu Et Al. [48] analyzed the spalling corrosion properties of 2024 and 7075 aluminium alloy friction stir welding, and found that 2024 aluminium alloy has the best corrosion resistance and the maximum corrosion depth is about 0.6 mm smaller than 7075 base metal. The discontinuous grain boundary precipitates and the 2024 Aluminium Alloy Zone in the agitator side can reduce the intergranular corrosion on the advancing side. At the same time, it is pointed out that different grain size leads to different susceptibility to intergranular corrosion, and the fine recrystallized grains at the forward side of the welded joint show higher susceptibility to intergranular corrosion than that of the base metal.

The results of Holtz et al show that the corrosion fatigue properties of 5083-H131 aluminum alloy are related to grain boundary precipitates. Mc Mahon et Al [50] studied the corrosion susceptibility of two alloys with different compositions (AA5083 and AA5456) under tempering conditions (- h131,-H116 and-SHTQ) . For constant-H116 high temperature, AA5456 rich in MG is less sensitive to intergranular stress corrosion than AA5083. Due to the low corrosion resistance of 2xxx and 7xxx aluminum alloys, the main research on corrosion fatigue is focused on 2xxx and 7xxx aluminum alloys, but less on 6xxx and 8xxx aluminum alloys. The effect of Cu content on the metastable pitting corrosion behavior of 6xxx series aluminum alloy was investigated by Kairy et Al. . It is concluded that over-aging treatment will form larger precipitates and have the greatest resistance to pitting. The results show that the pitting rate decreases with the increase of Cu content in 0.1 mol/l nacl solution. Because of the active chemical property of Li, al-Li alloys are more sensitive to corrosion in complex environments. At present, a great deal of research has been devoted to changing the types and distribution of precipitates by alloying and heat treatment, so as to improve the corrosion sensitivity of alloys. AA8090-T81 alloy is easy to be damaged by pitting corrosion in seawater, and the inhomogeneity of microstructure will increase its pitting sensitivity, while the grain boundary of AA2090Al-Li alloy will have Al2Cu phase during aging treatment, the precipitation-free zone (PFZ) with poor Cu was formed along the grain boundary and the edge of the dislocation precipitates of Al2cu Li phase.The composition affects the organization, the organization decides the performance, the different composition material has the different corrosion resistance, the addition element difference also can cause the corrosion resistance change, but the material organization, the precipitated phase, the heat treatment and so on all can affect the corrosion sensitivity change, the corrosion fatigue properties of different materials have their own characteristics and need to be studied extensively.

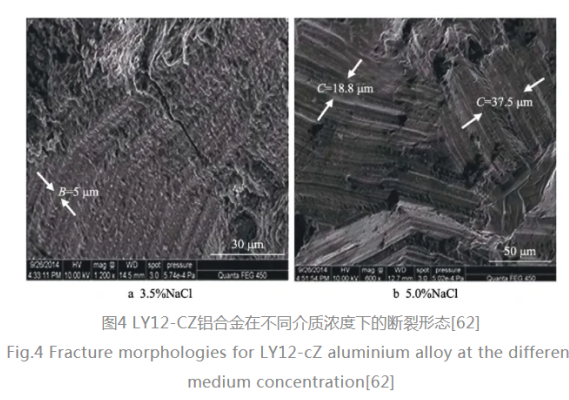

3.2 environmental factors 3.2.1 the influence of medium and concentration on the corrosion environment of aluminum alloy used in aeronautics and astronautics has obvious regional characteristics. The effects of humid atmosphere and industrial atmosphere on materials are found in the inland environment, and the effects of marine atmosphere and seawater on materials are found in the coastal environment. Due to the corrosion environment of high oxygen content and high salt spray formed in the ocean atmosphere and seawater, the fatigue properties of materials are especially affected. NACL SOLUTION WITH MASS FRACTION OF 3% ~ 3.5% is often used to simulate marine environmental experiments in laboratory. The effect of different corrosion media on the corrosion fatigue life of 7xxx aluminum alloy was found in the order of “OIL TANK WATER & GT; Salt Water & GT; Salt Spray & GT; Humid Air & GT; Laboratory Air”, it was found that the existence of Cl-in corrosive medium would aggravate the stress concentration effect of the specimen. In addition, the effect of different corrosion media on the fatigue crack growth rate is also different. The crack growth rate of 7xxx series aluminum alloy in 3.5% NACL corrosion environment is twice as high as that in air. In the range of low something K, the crack growth rate of Ly12-cz in brine is 3 times as fast as that in air.

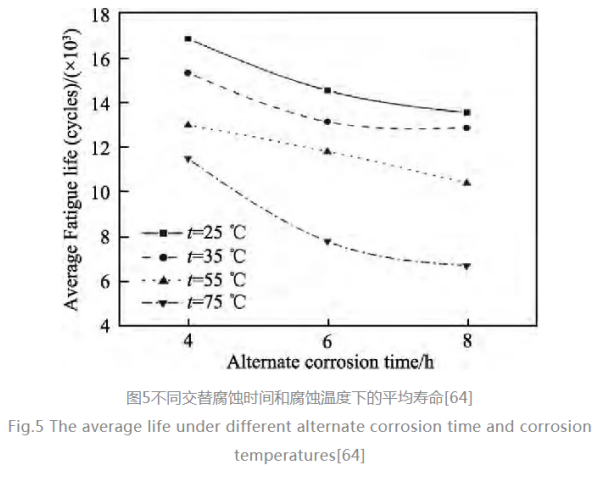

3.2.2 the influence of temperature and humidity on the corrosion fatigue life of high strength aluminum alloy. In high humidity environment, the content of Water Vapor and oxygen is high, so it is easy to react on the surface of the material to produce atomic hydrogen, which causes hydrogen embrittlement and accelerates the crack growth rate under cyclic loading. With the decrease of humidity, the crack growth rate decreases, which is proved by the experiments of crack growth in air and moist air. Higher temperature will increase the activity of the medium, accelerate the chemical reaction of the corrosive medium on the surface of the sample, accelerate the formation of the corrosion pit, and promote the crack initiation. The corrosion fatigue life of high strength aluminum alloy decreases at high corrosion temperature. As shown in Fig. 5, the average fatigue life of the alloy decreases when the corrosion temperature increases from 25 °C to 75 °C, and the higher the temperature, the more the average fatigue life decreases.

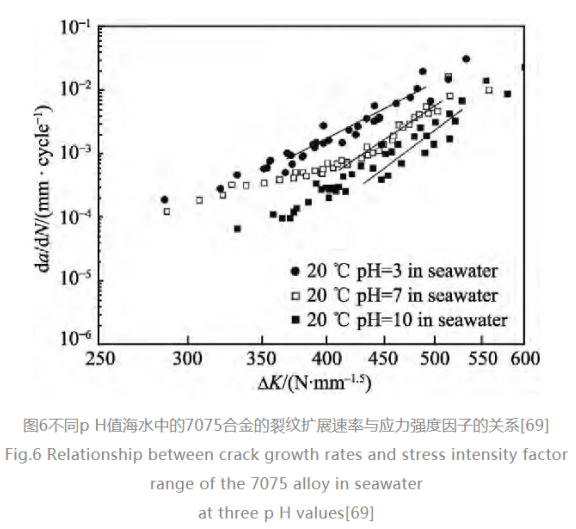

3.2.3 P H effect on high strength aluminum alloy in 2[65-66] . The variation of crack growth rate of aerospace aluminum alloy 7075 at different Ph values is shown in Fig. 6. With the decrease of Ph value, the solution corrosivity increases, the alloy’s critical Stress intensity factor decreases, and the crack growth rate increases, accelerated the destruction of corrosion fatigue. In the acid corrosion environment, the decrease of Ph value will lead to the increase of hydrogen ion concentration, promote the dissolution of passivation film on the surface of high strength aluminum alloy, lead to hydrogen embrittlement or promote crack propagation through the dissolution of Metal Anode; The accelerated action of fatigue crack growth is mainly caused by anodic dissolution, and in alkaline corrosion environment, as a result of the occurrence of Al (Oh)3 and other hydroxide precipitates in the solution, the passivation film is formed, and the anodic dissolution at the crack tip is restrained, the crack growth rate decreases. It is found that stable oxide film can be formed on the surface of 2024-T351 aluminum alloy in NACL SOLUTION WITH PH = 5 ~ 7, and it is difficult to form stable oxide film on the surface of 2024-T351 aluminum alloy in NACL solution with P H = 3, the Matrix metal is dissolved in direct contact with the corrosion solution. The value of Ph is 2 ~ 7 when the influence of Marine Environment is studied in laboratory.

3.3 Mechanical Factor 3.3.1 the effect of stress ratio on the corrosion fatigue crack growth rate is significant. Generally speaking, with the increase of stress ratio, the crack growth rate increases gradually. The DA/D N-SOMETHING K curves under different stress Ratios (R = 0.1,0.3,0.5) were measured by Li Chun-yan et Al. [70] . Sabelkin et AL [71] studied the transformation process from corrosion pit to crack in 7075-T6 aluminum alloy in 3.5% salt water. It was found that the crack initiation period decreased with the increase of fatigue stress in the same corrosion environment. The pre-corrosion experiments of 2024-T62 aluminum alloy under different stress ratios were carried out by Liu et Al. . It was found that the small crack effect existed when r =-1, but did not exist when r = 0.06 in the laboratory air, and R =-1,0.06 in 3.5% NACL solution, there is no small crack effect, which indicates that the effect of small crack is not obvious under pre-corrosion. However, when r = 0.06, the effect of different corrosion media on crack propagation is basically the same. The corrosion fatigue crack growth rate has an obvious threshold characteristic. According to Paris formula, it increases with the increase of Stress intensity factor K, but when the latter approaches the threshold value, the crack growth rate increases with the increase of stress ratio. In the high δk level region, the crack growth rate is similar under different stress ratios. It can be concluded that the stress ratio mainly influences the corrosion fatigue crack growth near the threshold region.

3.3.2 loading frequency has an important effect on the crack growth rate, but its mechanism needs further verification. It is generally accepted that lower frequencies are more conducive to the synergistic effect between the corrosive environment and the cyclic loading, and are more conducive to crack propagation. At 1ー10hz, the lower the loading frequency is, the higher the corrosion fatigue crack propagation rate is. It is explained that the lower the loading frequency is, the longer the corrosion time is, and the hydrogen produced by the corrosion is diffused sufficiently from the crack tip to the interior, resulting in hydrogen embrittlement, accelerated crack growth. However, when the frequency is less than 1 HZ, the crack growth rate is obviously lower than that at higher frequency, and there is almost no difference between 0.1 Hz and 1 Hz. Menan et Al. [75] found that there is a negative frequency dependence, that is, the crack growth rate of Al-Cu-Mg alloy in salt solution decreases with the decrease of frequency, and a similar effect has been observed in Al-Zn-Mg alloy. Two hypotheses are proposed: one is the crack closure effect at low frequency, and the effect is saturated in this frequency range; The other is the competition between the formation of passive film and the mechanism of anodic dissolution and/or hydrogen embrittlement. Li Xudong et Al. (1997) proposed a model of the effect of loading frequency on the corrosion fatigue crack growth rate of aeronautical aluminum alloys. Shafiq et Al [78] also show that the corrosion fatigue crack growth rate decreases with the increase of loading frequency at lower loading frequency, and the effect of loading frequency on crack growth is closely related to the corrosion resistance of materials. Therefore, the effect of frequency on the corrosion fatigue crack growth rate has not been clarified. It is necessary to study the effect of frequency on the corrosion fatigue crack growth.

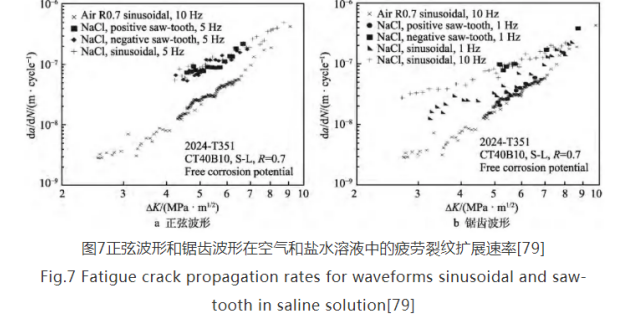

3.3.3 loading waveform effect waveform as a function of frequency and Stress intensity factor (δKi) , mainly affects the corrosion fatigue properties of aluminum alloys in terms of frequency and holding time. Loading waveform includes sine wave, triangular wave, square wave wave, Sawtooth wave and so on. No matter what the waveform is, the longer the holding time is in high stress area, the higher the crack growth rate (FCGRS) will be. Menan et Al. [79] studied the variation of the crack growth rate (FCGRs) of the 2024 aluminium alloy under sinusoidal and Sawtooth waves. As shown in Fig. 7, FCGRs under negative sawtooth waves at a frequency of 1 Hz were similar to FCGRs measured at high frequencies, higher than FCGRs measured at the same frequency under sinusoidal signal. In the case of positive sawtooth wave, the propagation of the same frequency is slower than that of the sine wave, regardless of the period duration. Kuanglin et Al. [80] carried out fatigue tests on uncorroded specimens in high-low loading sequence, and found that the critical cumulative damage is less than 1, while the critical cumulative damage is more than 1 under low-high loading sequence. However, the fatigue damage accumulation law of pre-corroded specimens presents the opposite law.

4 conclusion and prospect the research status of corrosion fatigue of aerospace aluminum alloy in recent years is reviewed in this paper. Corrosion fatigue is a very complex problem, and the influencing factors are complex and changeable. At present, the research mainly focuses on pre-corrosion fatigue, and the research on corrosion fatigue under corrosion-fatigue synergy/alternation is still in the initial stage, the mechanism of crack initiation and propagation, the effect of fatigue properties and fatigue life under the synergistic effect of corrosion and fatigue are still to be further explored, the following aspects still need to be further studied: 1) the change rule of fatigue behavior and related mechanism under corrosion-fatigue synergistic/alternating action. The study of corrosion fatigue is to accurately obtain the fatigue life prediction under various influence factors, different corrosion fatigue mechanism and different crack forms, and to establish a model which can effectively predict the corrosion fatigue life. 2) equivalent corrosion time. In the corrosion fatigue test, the accelerated corrosion test is usually carried out in the accelerated corrosion environment, but there is no mature equivalent relationship between the actual corrosion time in the natural environment and the corrosion time established in the laboratory, so it is difficult to ensure the credibility of the test results in the accelerated corrosion study in the laboratory. 3) corrosion fatigue damage evolution. The damage evolution of corrosion fatigue is a very complex problem, which is highly dependent on materials and environment. A lot of experiments are needed to study the damage evolution model of corrosion fatigue. 4) the combination of numerical simulation and experimental research. It is of great significance to study corrosion fatigue of aluminum alloy by combining theory with practice, that is, combining numerical simulation with experimental research.

Source: China Corrosion & Protection Network

Disclaimer: Some pictures and texts on this site are collected from the Internet and are only for learning and communication. The copyright belongs to the original author and does not represent the views of our site. This site will not bear any legal responsibility. If your rights are violated, please contact us to delete it in time.