Good Industry Knowledge, on the photovoltaic welding strip market structure detailed analysis

Release time:2022-02-11Click:974

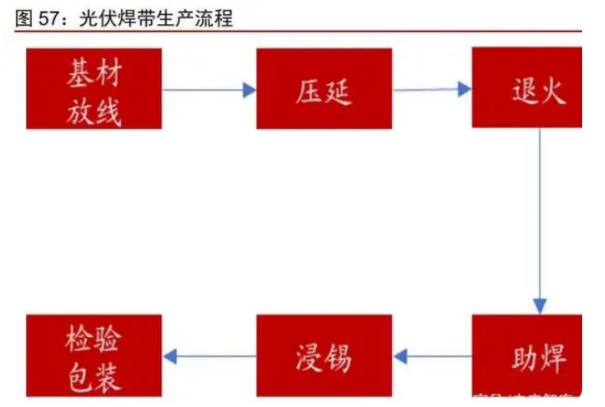

Photovoltaic Welding Strip small and beautiful, market concentration is expected to improve. 1. Brief introduction of photovoltaic welding tape the main cost of photovoltaic welding tape is raw material cost. Photovoltaic welding strip is an important raw material in the welding process of pv module, also called tinned copper strip or tinned copper strip, which can be divided into interconnect welding strip and conflux welding strip. The interconnect welding strip is used for connecting the photovoltaic cell slice, and the confluent welding strip is used for connecting the photovoltaic cell string and the junction box. The photovoltaic welding strip is mainly made of copper substrate, tin alloy coating and flux. The raw material cost accounts for more than 90% of the production cost. In the production of photovoltaic welding strip, copper substrate is first drawn and rolled, then annealed, soldered and finally dipped into tin to obtain the finished product. There are many types of photovoltaic welding strip, and MBB welding strip is widely used. According to the performance and field of application, photovoltaic welding tape can be divided into many types. The interconnect welding belt mainly includes the conventional interconnect welding belt, MBB welding belt, low temperature welding belt, low resistance welding belt, etc. . At present, the mainstream PV products on the market are MBB welding strips suitable for multi-grid components, which are thinner than the conventional welding strips, which is helpful to reduce the shading to the battery sheet, and make more effective use of sunlight, at the same time, increasing the number of the main grid can shorten the current collecting path, reduce the series resistance and reduce the power loss of the battery.

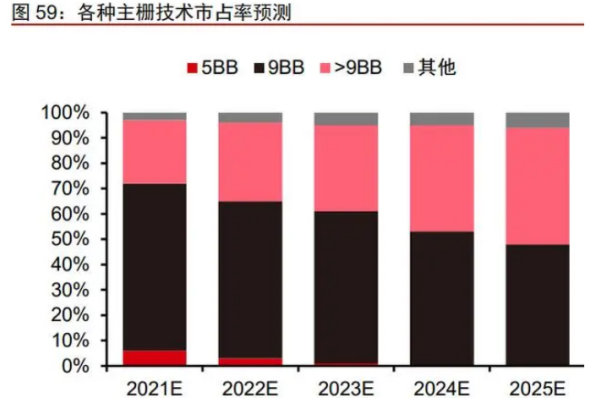

2. Demand continues to grow, component technology changes bring different patterns of Welding Strip market full competition, demand continued to grow. Photovoltaic welding strip industry has a high degree of marketing, competition pattern is more scattered. The Industry Has Independent R & D, production capacity of photovoltaic welding strip manufacturers more than 20, including Suzhou Yubang, sharing technology, Xi'an Tailisong, Weiteng Electric, Taicang Juren, Suzhou Saili, Jiangsu Sun technology larger scale. From the demand side, with the increase of the downstream installed capacity, the demand for strip welding is expected to continue to grow, we forecast 218,000 tons of photovoltaic strip welding demand in 2025, CAGR for 17.6% . The change of the pattern of upstream welding strip driven by the change of component technology. The multi-gate technology can reduce the shading area of the pv welding strip, shorten the current collecting path, reduce the series resistance, reduce the power loss of the PV module, and improve the efficiency of the pv module. According to the CPIA, the market share of technologies above 9 main grids will continue to increase, which will lead to a change in demand for multi-main grids. Compared with the traditional component, the imbricate component has many advantages, such as higher conversion efficiency and power, less occlusion effect and so on. With the gradual popularization of imbricate components, the demand of imbricate welding strip will also be increased correspondingly.

3. Conductive adhesive or part of the conductive adhesive instead of photovoltaic welding tape is conductive adhesive, similar to the function of photovoltaic welding tape. Conductive adhesive is a curing or drying with conductive adhesive. Similar to the photovoltaic welding tape, it can connect a variety of conductive materials together, so that the materials being connected to form an electrical path. Conductive adhesive is composed of Resin Matrix, conductive particles, diluent, cross-linking agent and toughening agent. The Matrix mainly includes epoxy, silicone resin, polyimide resin, acrylate resin, polychlorinated polyester and so on. Conductive adhesives can be divided into silver conductive adhesives, gold conductive adhesives, copper conductive adhesives and carbon, carbon conductive adhesives, the most widely used is silver conductive adhesives.Photovoltaic conductive adhesive technology is controlled by foreign manufacturers, domestic cost reduction is expected to scale application. Imbricate module has higher request to conductive adhesive, conductivity, bonding effect, curing time, this also caused the production of pv conductive adhesive has certain technical barriers. At present, the supplier of pv conductive adhesive are German Henkel, Debon, Heraeus and Suzhou Ruilibo, the listed company Tianxin, material of pv conductive adhesive has been successful in the benchmark customer first single supply. Compared with pv welding tape, the cost of pv conductive adhesive is much higher, which is the most important factor restricting its scale application. With the continuous research and development of domestic enterprises, home-made breakthrough in cost reduction, home-made photovoltaic conductive compound will also be widely used in photovoltaic cell connection.

Source: think tank of the future

Disclaimer: Some pictures and texts on this site are collected from the Internet and are only for learning and communication. The copyright belongs to the original author and does not represent the views of our site. This site will not bear any legal responsibility. If your rights are violated, please contact us to delete it in time.