Study on ultrasonic micro-tensile test of t-2 red copper sheet

Release time:2021-03-25Click:907

ABSTRACT: during the forming process of large-scale sheet metal parts, ultrasonic is widely used to reduce the friction between blank and die and to improve the forming limit of sheet metal. However, the application of ultrasound in the micro-forming of sheet metal is seldom reported. In this paper, the Mechanical Properties of Metal Sheet under ultrasonic environment were obtained by adding ultrasonic to T2 copper sheet through designing a suitable ultrasonic device based on conventional tensile experimental equipment.

Keywords: ultrasound; t2 Copper Sheet; Mechanical Properties; micro-stretch, author: Gu Xiaomeng

1. Introduction

The miniaturization of products has put forward higher requirements for the processing of parts, and the research and application of micro-parts have developed rapidly since the beginning of the twenty-one th century. Sheet Metal micro-forming is an important way to manufacture micro-parts. The basic mechanical properties of micro-forming materials have an important influence on the selection of forming process and the formulation of process parameters. In the plastic forming process of metal materials, ultrasonic vibration with different directions and amplitudes will change the mechanical properties of metal materials, such as yield strength, tensile strength, flow stress and deformation resistance, the processing quality of the material is improved. The deformation law and mechanical properties of micro-forming materials under ultrasonic environment is an important research topic, but the research and the published technical achievements are few at present. In this paper, the Mechanical Properties of Metal Sheet under ultrasonic environment were obtained by adding ultrasonic to T2 copper sheet through designing a suitable ultrasonic device based on conventional tensile experimental equipment.

1 in the design of ultrasonic tensile device,

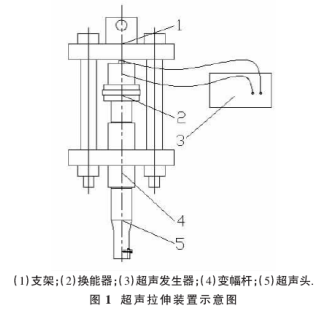

the tensile specimen is clamped on the ultrasonic head to attach the ultrasonic vibration to the tensile specimen. In this paper, an ultrasonic stretching device is designed, the rated power is 1kW, the frequency is 20kHz, the amplitude is adjustable in three grades. The basic structure is shown in figure 1.

The clamping device of the tensile testing machine can not be used with the designed ultrasonic tensile device. A new bottom clamp is needed to hold the other end of the tensile sample. The ultrasonic head of the ultrasonic stretching device is rotatable, therefore, it needs to be flexible enough when designing the bottom fixture. The bottom fixture is made of steel plate, as shown in figure 2. The bottom plate can be rotated and the middle plate can be moved horizontally.

By measuring the amplitudes of the different gear positions of the ultrasonic stretching device, the amplitudes of the ultrasonic head end face are measured as shown in Table 1.

2. Preparation of tensile specimens

2.1 heat treatment

T2 Red Copper Sheet was selected as the test material in this experiment. Its delivery state is rolled state and its thickness is 0.1 mm. The thickness/grain size ratio is an important parameter which affects the Mechanical Properties of Metal Sheet. In this paper, the effect of ultrasonic vibration with different amplitude on the mechanical properties of T2 copper thin plate is studied by using thickness/grain size ratio as a basic parameter. In order to obtain groups of T2 copper thin plates with different thickness/grain size ratios, it is necessary to Anneal t2 copper thin plates at different temperatures. The heating time and holding time of annealing treatment of T2 copper sheet are shown in Table 2. The cooling method is furnace cooling. The resulting thickness/grain is shown in table 3.

2.2 sample preparation in this experiment, T2 copper thin plate is thin, rigidity is not enough, single slice WEDM is not convenient in clamping and cutting, so when preparing tensile sample, several layers of T2 copper thin plate are added to clamp and cut. After WEDM, a large amount of dirt is adhered to the surface and edge of the tensile specimen, which needs to be cleaned and dried with alcohol solution. Figure 3 shows the WEDM tensile specimen and the remaining scrap.

3. Results and analysis of ultrasonic microtensile test

Using the designed ultrasonic stretching device to carry out the experiment, before the specimen is clamped, the ultrasonic stretching device needs to be adjusted, so that when the ultrasonic stretching device and the bottom clamp clamp clamp are in the same plane, after the debugging is completed, the tensile test of T2 copper sheet with thickness of 0.1 mm was carried out under different thickness/grain size ratio and different ultrasonic amplitude for 3 ~ 5 times.

Analysis of mechanical properties of 3.1 ultrasonic microtensile

The mechanical properties of the tensile specimen of T2 copper with different thickness/grain size ratios were obtained by ultrasonic vibration with different amplitudes as shown in tables 4 and 5 respectively. As can be seen from table 4 and Table 5, the yield strength and tensile strength of T2 red copper sheet decreased with the application of ultrasound compared with that without ultrasound, but the effect of ultrasonic vibration on different thickness/grain size ratio is different.

3.2 the effect of different ultrasonic amplitudes

on the mechanical properties of the same thickness/grain size ratio during the ultrasonic micro-tensile test of T2 copper sheet, the "softening effect" and "hardening effect" of ultrasonic vibration on T2 copper sheet were found. The engineering Stress–strain curve shown in figure 5 was obtained by ultrasonic stretching of a T2 copper sheet tensile specimen with a thickness/grain size ratio of 28.6. From Fig. 5, it is obvious that the deformation resistance of T2 copper sheet decreases after ultrasonic treatment, that is, there is ultrasonic softening effect, but it is different from the results of ultrasonic tensile test

In the experiment, the reduction of deformation resistance is positively correlated with the ultrasonic amplitude, that is, the larger the amplitude, the greater the reduction of deformation resistance. In the curve shown in Fig. 5, the reduction of deformation resistance decreases with the increase of ultrasonic amplitude, i. e. , the reduction of deformation resistance with ultrasonic amplitude of 5.58 M is smaller than that with ultrasonic amplitude of 3.02 m. The possible reason for this is that there exists an ultrasonic vibration amplitude less than 3.2 m for the thin T2 copper plate with a thickness/grain size ratio of 28.6, and the deformation resistance decreases the most under the action of ultrasonic, then with the increase of ultrasonic amplitude, the decrease of deformation resistance becomes smaller and smaller until a critical value is reached, and the decrease does not change with the increase of ultrasonic amplitude. The critical value is lower than the deformation resistance obtained without ultrasonic micro-stretching.

0.2 m ultrasonic vibration and the curve obtained after 90 s ultrasonic vibration cancellation. As can be seen from Fig. 6, the stress decreases sharply and reaches a minimum value at the moment of applying longitudinal ultrasonic vibration, when the minimum value is reached, it immediately rises back to a value smaller than that without ultrasonic stretching, and then enters into the stage of longitudinal ultrasonic micro-stretching. When the Longitudinal ultrasonic is withdrawn, the stress also appears a sharp drop, and then rises, a return to a value greater than that applied to the longitudinal ultrasound is followed by a stabilization phase. The experimental curves were compared with those of ultrasonic Longitudinal microtensile test with thickness/grain size ratio of 28.6 and ultrasonic amplitude of 3.02 m, and the two curves were in agreement with some of the curves in Fig. 6. At the moment of applying and canceling ultrasonic vibration, the stress changes rapidly, which can be considered as the "stress superimposition" of the force and the tensile force produced by ultrasonic vibration, which causes the "softening effect" of the T2 copper sheet.

3.3 the effect of the same ultrasonic amplitude on the mechanical properties of different thickness/grain size ratio

In the absence of ultrasonic, the tensile strength of T2 copper sheet increases with the increase of thickness/grain size ratio, but the tensile strength obtained by applying ultrasonic vibration with amplitude of 3.02 m is as shown in Fig. 7, the tensile strength does not increase with the increase of thickness/grain size ratio, but reaches its maximum when the thickness/grain size ratio is 8.1. The difference between the tensile strength without ultrasound and the tensile strength with amplitude of 3.02 m is obtained, that is, the reduction of the tensile strength. It is obvious that the tensile strength decreases the most when the ratio of thickness to grain size is 8.1 under 3.02 m longitudinal ultrasound.

In the absence of ultrasonic, the tensile strength of T2 copper sheet increases with the increase of thickness/grain size ratio, but the tensile strength obtained by applying ultrasonic vibration with amplitude of 3.02 m is as shown in Fig. 7, the tensile strength does not increase with the increase of thickness/grain size ratio, but reaches its maximum when the thickness/grain size ratio is 8.1. The difference between the tensile strength without ultrasound and the tensile strength with amplitude of 3.02 m is obtained, that is, the reduction of the tensile strength. It is obvious that the tensile strength decreases the most when the ratio of thickness to grain size is 8.1 under 3.02 m longitudinal ultrasound.

4. Conclusion up to now,

the application of ultrasonic vibration to the study of mechanical properties of metal sheet in micro-tensile experiment is rare. In this paper, different amplitudes of ultrasonic vibration are applied to the micro-tensile experiment of T2 copper sheet, the effect of ultrasonic vibration with different amplitudes on the mechanical properties of T2 copper sheet was studied. The yield strength and tensile strength of T2 copper sheet were decreased in different degree by ultrasonic treatment, but the effect of ultrasonic treatment on thickness/grain size ratio was different, and the effect of ultrasonic treatment on yield strength and tensile strength of T2 copper sheet was different, the results show that the deformation resistance of T2 copper plate decreases, and the decrease amplitude is the largest at 3.02 m and the smallest at 5.58 m.

Source: Chinanews.com, by Gu Xiaomeng

Disclaimer: Some pictures and texts on this site are collected from the Internet and are only for learning and communication. The copyright belongs to the original author and does not represent the views of our site. This site will not bear any legal responsibility. If your rights are violated, please contact us to delete it in time.